Chemsafety

Process development

Consulting

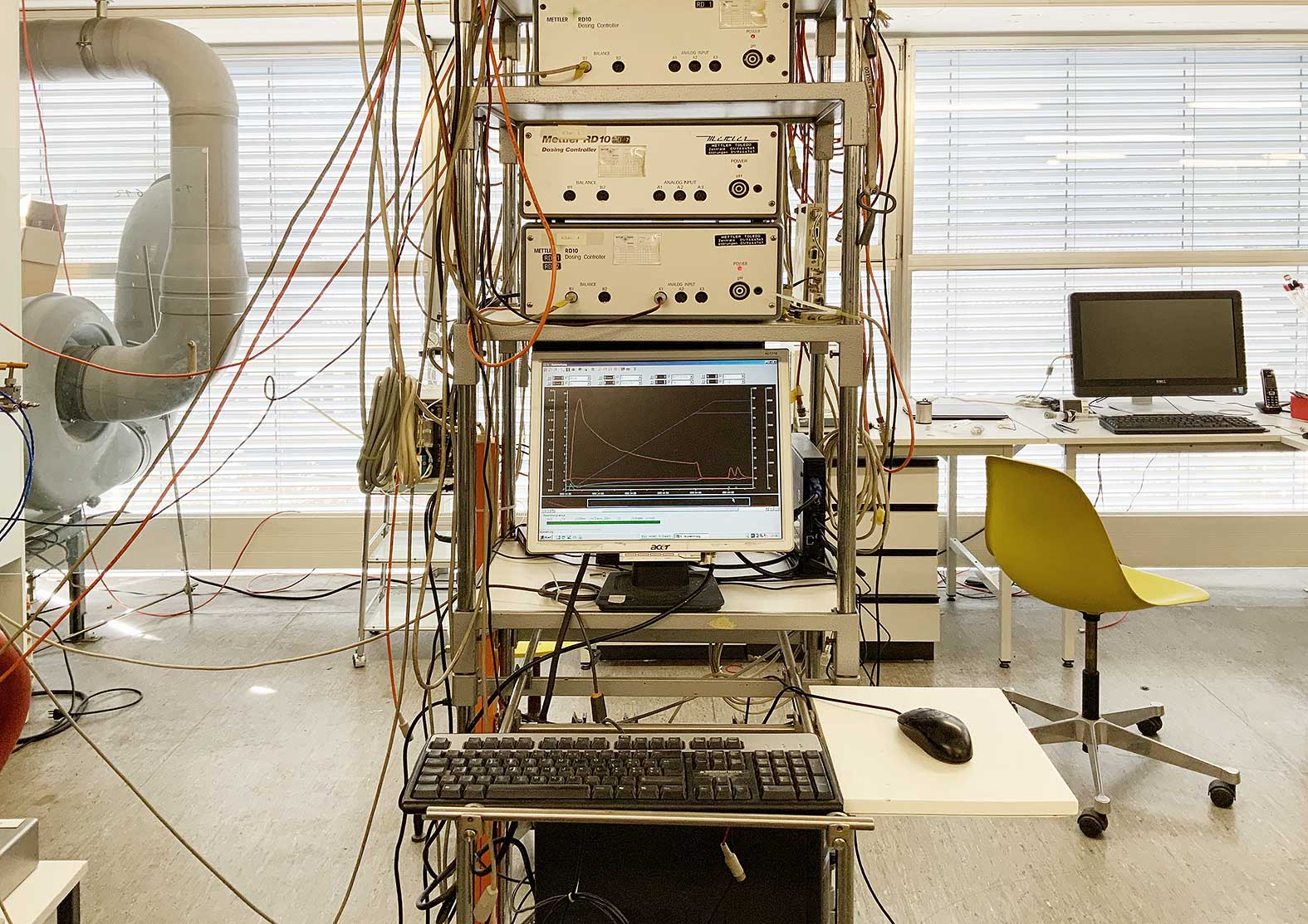

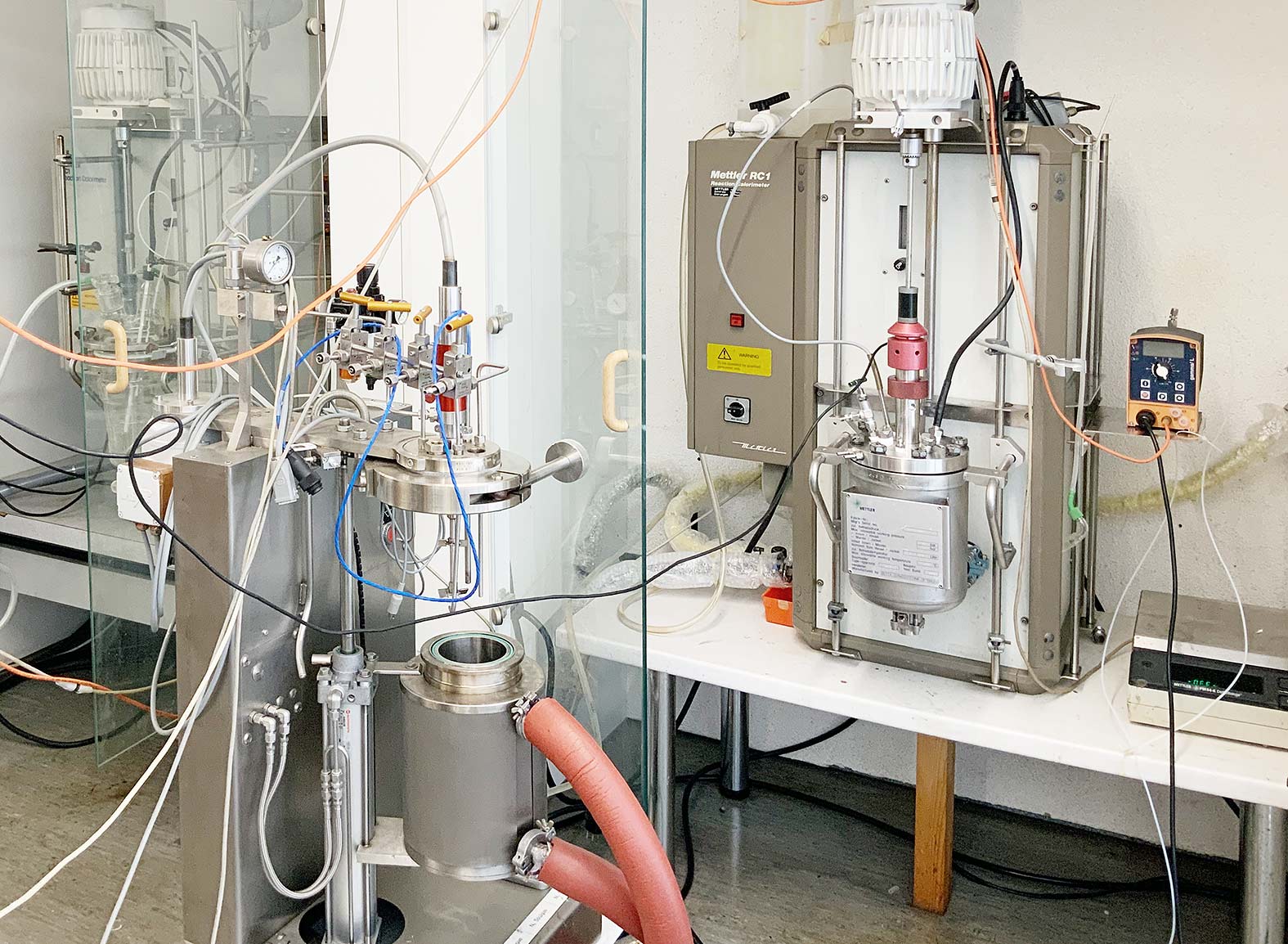

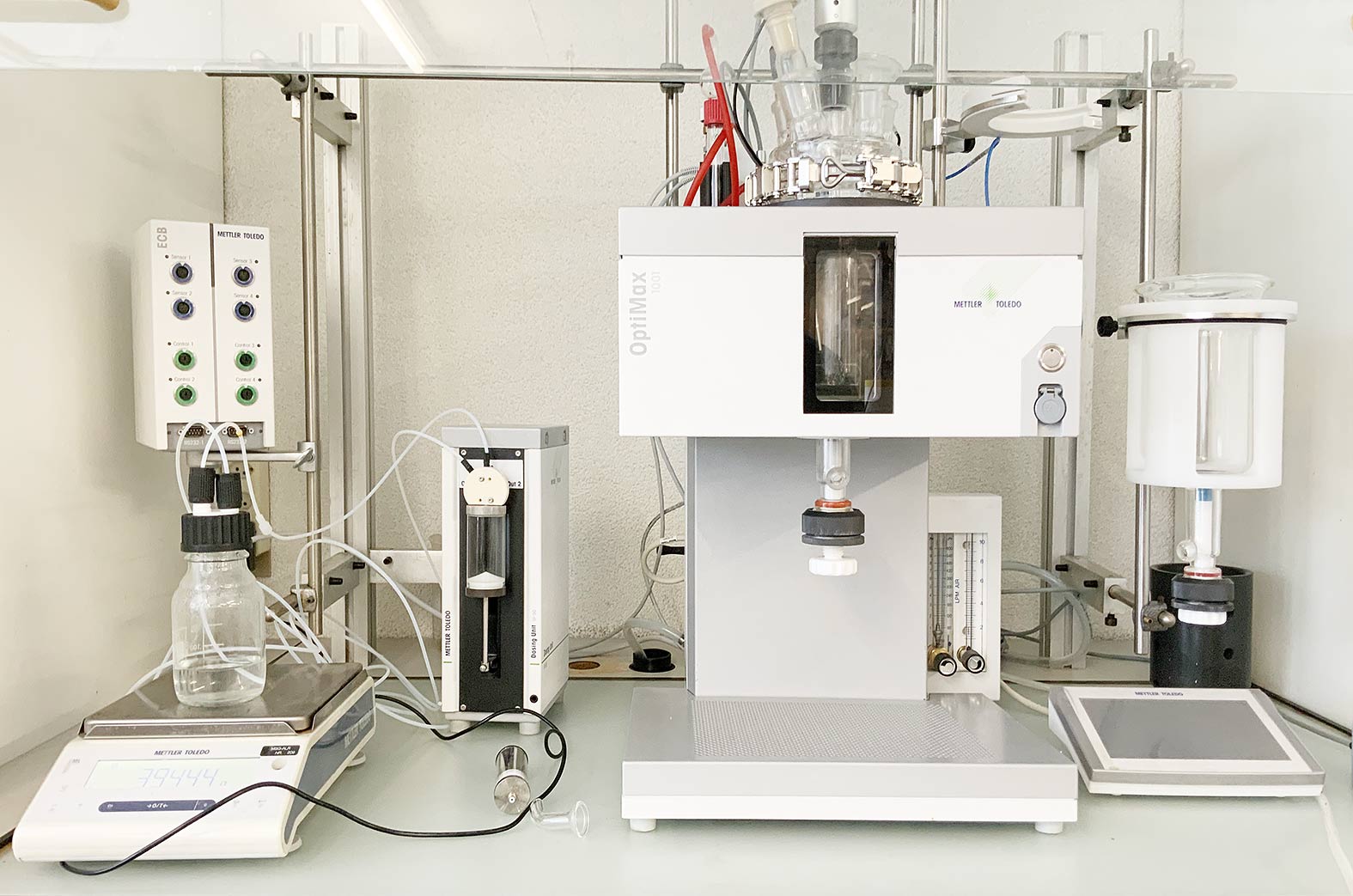

Comprehensive process knowledge is the basis for the development of safety-integrated chemical processes and for the development of ecological integrated production processes.

We carry out the necessary studies in our laboratory and adapt the new procedures to the desired requirements.

WHAT WE DO

Changed market conditions require a high flexibility of multi-product chemistry. It is becoming increasingly important to carry out more complicate syntheses of high-quality products on a production scale. The requirements for the chemical process are influenced by various factors. In addition to traditional factors, market situation, profitability and quality, the development of a chemical process is more and more influenced by new factors such as process safety, environmental safety, quality assurance and of the approval situation.

COMPETENCES & PRODUCTS

On the basis of our extensive measurement and testing options, our core competencies, we develop holistic solutions to problems relating to chemical processes.

Our core products are the identification of the inherent dangers of all process steps of chemical processes and the development of safe chemical processes.